Once all the details are worked out, we accept the order from the customer for processing. We also prepare box patterns, templates and inserts and send them to the customer to add graphic design.

The sales representative uploads them to our platform, and then we wait for the graphic files. Once we receive them, our graphics department checks everything for compliance with offset printing technology and our standards.

After verification of the received files we prepare and send digital ozalids — files with printed elements imposed on sheets – for approval.

Upon request, we can also provide a colour proof in the form of a certified printout, nearly identical to offset print.

The planning department sets deadlines for each stage, and the production preparation department registers all the required operations.

Fun fact! We register xxx production operations per year. (Each production process consists of many operations)

The order goes to the CTP department, where plates are exposed for printing.

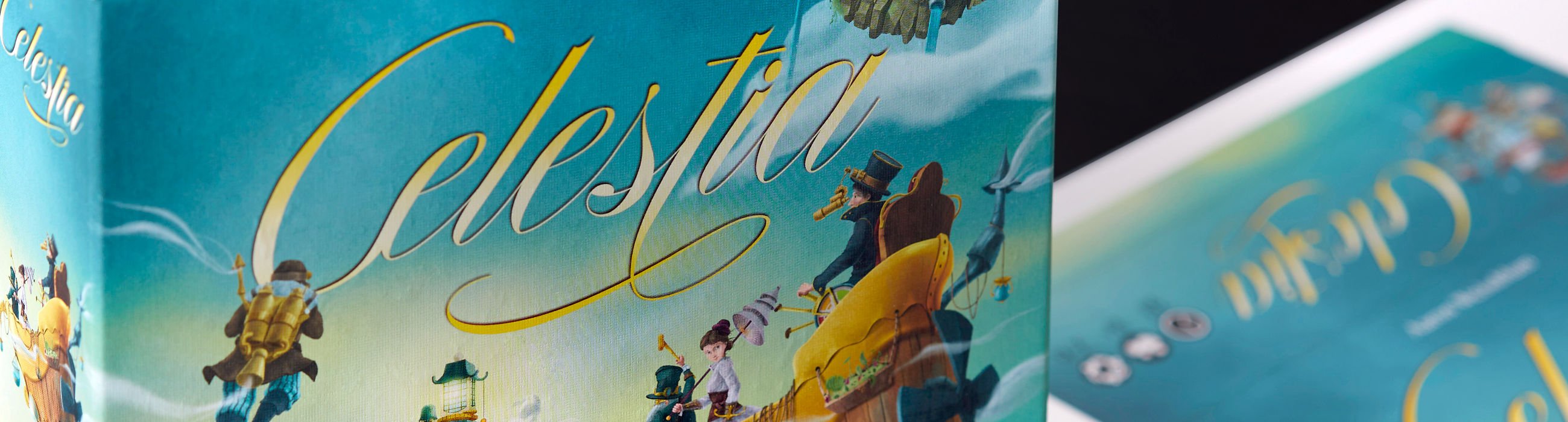

The process of printing individual elements begins.

We print box finishes, boards and templates, as well as rule books and game manuals.

Both sides of printed cards of various formats are coated with professional card varnish, characterised by top-of-the-line parameters.

Specialised machines cut out cards with rounded corners, ensuring the highest precision. The cards are then packed in plastic, biodegradable cellophane or a paper band.

We make cardboard elements. We laminate and stamp box elements, templates and boards.

We order other components such as dice and tokens, as well as plastic mouldings from our partners.

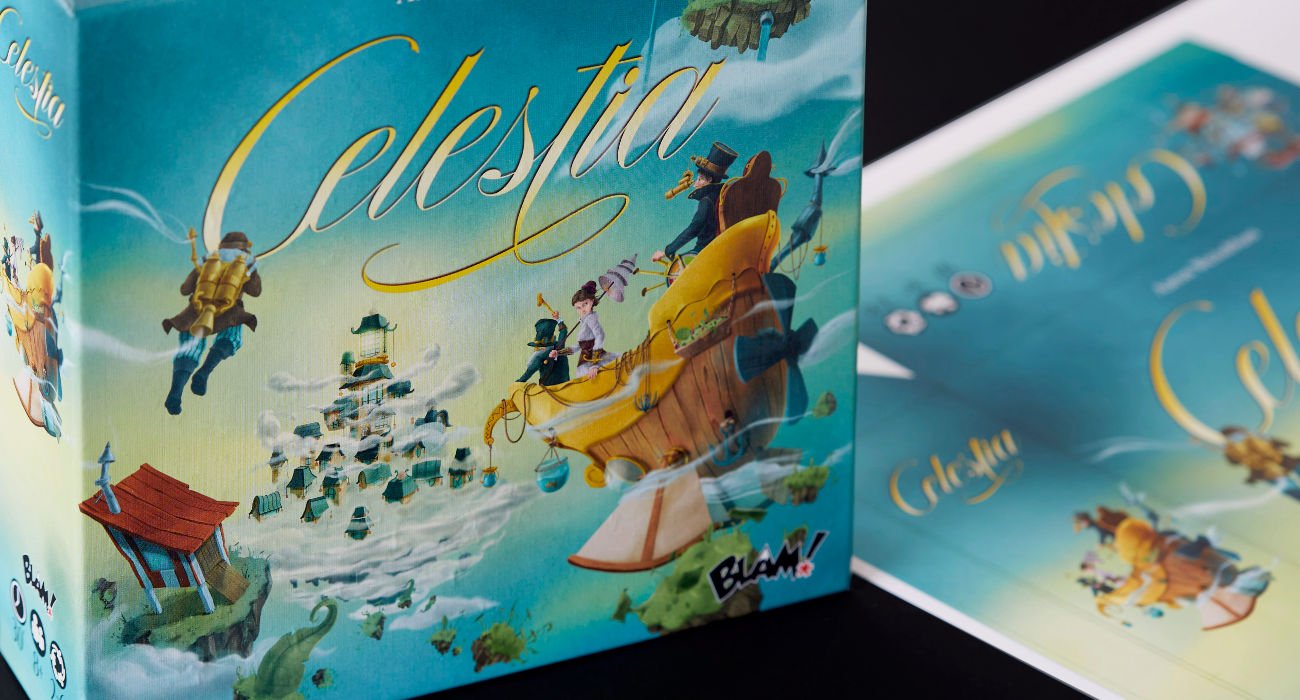

When all components are ready we move on to boxing the game.

At each of the above stages, we carefully and thoroughly inspect the elements of the game so that we can be sure that the finished product will conform with the most stringent quality standards.

We work with carriers offering road transport services within Europe and sea transport for shipments to other continents.

The finished products are packed according to the order in secondary packaging, to which we attach labels according to the customer's design. Then we put them on pallets, wrap them up and ship them to the indicated address.